In the industrial district of Modena, along the old Via Emilia, ZPZ Partners designed the new Tetra Pak Research Hub: they redefined the industrial typology and the workspace and established a connection with the existing buildings in the area.

From a distance, the structure appears as a large, opaque parallelepiped-shaped plastic object. It is sleek, pristine, capable of flexing and smoothly curving along its edges. Upon closer inspection, the large milk white-colored envelope reveals its structure and materiality. The visually soft and flexible surfaces are constructed with precast concrete panels. These panels, arranged in a regular pattern, create a seamless and uniform envelope. Triangular shapes, imprinted in the concrete panels, gradually diminish in size towards the top.

The surface of this large container slightly flexes on the southeast and northwest sides. On the ground floor, extensive glass bands provide a view of the interior and direct access to the workspace. The envelope ultimately reveals a complete opening on the northwest side, forming the main facade that houses the entrances and accommodates the office and laboratory spaces.

The office section appears to emerge from the volume of the building, detached from the plastic shell both on the sides and at the top. Between the second level of the offices and the shell, there is a spacious terrace area.

The design of the offices and laboratories has allowed Tetra Pak to experiment with work organization systems that promote innovation, based on the principles of Activity-Based Working and Agile Working.The workplace is designed with the understanding that a percentage of employees, ranging from 15% to 20%, will work from home. The physical office, therefore, becomes a hub for creative interaction, hosting activities that cannot be conducted remotely.

Arranged in an open, coordinated, and flexible layout, the offices align along the northwest-facing side of the room and form a separate building volume that appears independent from the container enveloping the structure on all other sides. In essence, the office section, organized over two levels, presents two fronts.

The internal front, which houses dedicated rooms, quiet environments, spaces for highly specialized activities, areas for design, and informal meeting places, establishes a direct visual relationship with the area where the packaging machine production takes place.

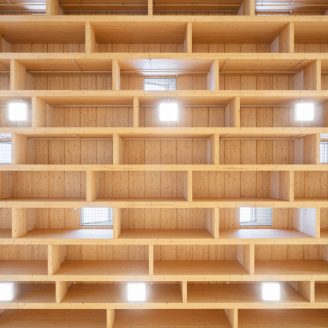

The external front, housing the managerial and administrative departments, defines the main facade of the production site. This facade is characterized by a fully glazed surface, organized in a grid pattern that follows an apparently irregular rhythm. The grid is made of wooden elements arranged orthogonally to the facade, providing shade from direct sunlight during the summer while reflecting the identity and environmental quality offered inside.

The uniqueness of this facility lies in its total flexibility. The new facility, which currently accommodates research and development activities, was conceived as an entirely transformable hangar, a hybrid workspace capable of hosting production lines or serving as a venue for events and training without the need for additional modifications.

The design challenge involved organizing a complex system of utilities and distribution, which essentially formed the building’s hardware. This hardware consisted of compressed air ducts, water and fluid channels for processing, electricity, and data infrastructure. The project reimagined the presence of these systems by creating a design that allows their access only when necessary, keeping them hidden for the rest of the time. Even the conveyor belts for recycling are located underground in two tunnels that are 7 meters wide and span the length of the building.

This approach to the industrial design has several advantages, including minimizing noise, creating extremely clean spaces, eliminating the view of processing waste, and facilitating recycling processes.

These characteristics, along with the idea of the workspace as a place of well-being, led ZPZ Partners to conceive the over 4,500 square meters of space dedicated to these functions as a single large hall. The hall features a white floor and glulam ceiling, free from structural obstacles except for two large lattice elements that serve as internal gardens. In addition to entering through these plant-filled structures, natural light diffuses into the hall through the gardens located between the offices, numerous skylights scattered in a free form on the roof, and two windows running at street level on the southwest and northeast facades.

The collaboration between the large central steel structural elements along the axis of the building and a series of perimeter steel columns has enabled the creation of a spacious and open space. Within this space, four production lines have been set up, with the capacity to accommodate up to 36 packaging machines, each supported by devices that ensure their complete functioning.

Both the conveyor belt and the primary distribution of utilities (treated cooling water, recycled packaging water, raw water, compressed air, and electricity) are located in two accessible corridors in the basement. Maintenance can be carried out outside the active area, keeping the testing hall clean and flexible.

The final image is pure and elegant. This solution also allows for the presence of visitors such as professionals, developers, and clients, creating a stimulating work environment conducive to strong team spirit.